No gravity? No problem. Associate professor successfully tests 3D printer in series of parabolic flights

Published: Jun 20, 2025 1:00 PM

By Joe McAdory

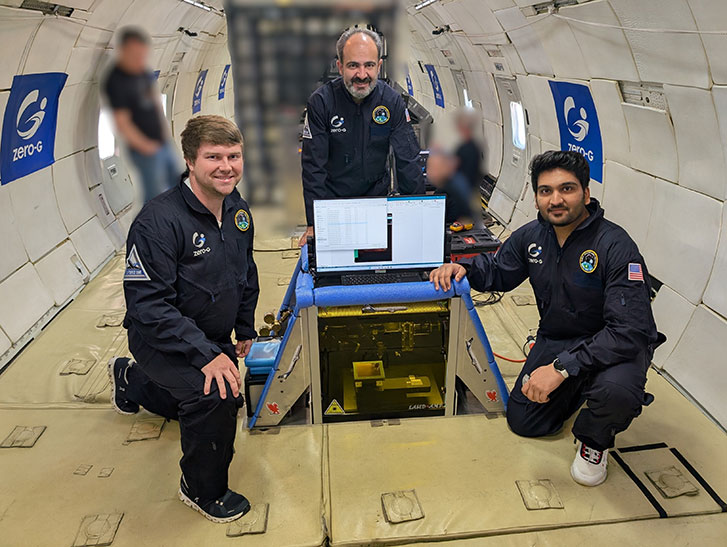

Masoud Mahjouri-Samani, Godbold Associate Professor in the Department of Electrical and Computer Engineering, successfully tested a compact nanoparticle 3D printer aboard a series of NASA-sponsored parabolic flights simulating zero gravity.

Conducted in May near Salina, Kansas, the test marked the airborne debut of LASED (Laser Ablation and Sintering Enable Deposition), a fully integrated, low-power system designed to fabricate circuits, sensors and antennas in space.

“This was a one-shot win. From the very first parabola, the machine printed beautifully. That level of success on a first flight is extremely rare,” said Mahjouri-Samani, who made the flights with graduate student Aarsh Patel and Colton Bevel, a research engineer at the Auburn University Research and Innovation Campus in Huntsville.

The project, “In Space Dry Printing Electronics and Semiconductor Devices,” received an $870,000 grant from NASA earlier this spring.

Aboard a modified Boeing 727 (often dubbed the “Vomit Comet”) the team experienced about 30 parabolic arcs, each offering roughly 23 to 25 seconds of microgravity.

The test pointed to a future where astronauts can build what they need in orbit, without relying on Earth-bound supply chains. In deep-space missions, low-earth orbits or long-duration International Space Station (ISS) deployments, the ability to print flexible, functional electronics on demand could be critical.

“In space, you want to print what you need, when you need it,” Mahjouri-Samani said. “That could be antennas, temperature or humidity sensors, crew health monitors — even chemical sensors. We can design and build our own circuits on site.”

The printer measures just 24 inches on each side and consumes less than 500 watts, making it ideal for use aboard the ISS or future lunar missions.

Despite its tiny footprint, the machine includes a nanoparticle generation system, a delivery mechanism via nozzle, and a sintering process — all fully automated.

“It’s a fully functional machine,” said Mahjouri-Samani, director of the Laser-Assisted Science and Engineering — Emerging Nanomaterials and Devices Laboratory. “Everything is integrated. You can program it to complete complex tasks in 20 seconds. In space, without that time constraint, it can do even more.”

The system was also engineered to withstand intense conditions.

“We did a lot of simulations and calculations to make sure it could survive takeoff, landing and the sharp G-force changes,” Mahjouri-Samani said. “Our machine was built to tolerate up to 18Gs — much more than the 2Gs the flight produced. So yes, we were too good.”

Mahjouri-Samani said the device’s plug-and-print performance exceeded even his own expectations.

“Other systems sometimes need multiple flights to even get one usable print,” he said. “Ours worked perfectly on parabola one. Once the programmed tests were completed, we had time to print more. We built in a margin for error, but we didn’t need it. We had time left, so we printed extra.

“We focused on foundational patterns this time,” he said. “But the real question was: would it print in zero gravity? The answer is ‘yes.’ This printer is highly automated. You just hit ‘print’ and let it go. It was stable, consistent and precise.”

Following the flight, Mahjouri-Samani submitted a short technical report to NASA reporting the outcome. A comprehensive report, including side-by-side comparisons of prints produced in microgravity and on the ground, measuring roughness, thickness, resistivity and other physical properties, will be followed shortly.

“The summary is… the machine works extremely well in zero gravity,” he said. “What we printed up there was either equal to, or in some cases better, than what we printed on Earth.”

Mahjouri-Samani, founder and president of dry multi-material printer startup NanoPrintek, is already planning for a second parabolic test.

“Next year, we’re going to try printing semiconductors,” he said. “We might also integrate other ideas to better simulate the space environment. If the printer works this well in 0G, maybe we should consider sending one to space. It’s stable, precise, and efficient — exactly what you want in orbit or beyond.

“This was one small step for our printer, one giant leap for space-based fabrication.”

Media Contact: , jem0040@auburn.edu, 334.844.3447

Masoud Mahjouri-Samani and researchers successfully tested this compact nanoparticle 3D printer in zero gravity.