Outside the box, inside the bottle: Biosystems engineering class features unconventional filtration project

Published: Feb 6, 2026 11:00 AM

By Rachel Wingard

“Found” materials — these are what the students in BSEN 2210 Engineering Methods for Biological Systems use to create water filters as part of their coursework.

According to Jonathan Davis, senior lecturer of biosystems engineering, these materials include anything that has not been previously manufactured.

“We do not provide any of the materials, so students are challenged to find their own,” he said. “They can only use materials you could find in nature or scrounge from any trash pile — no pre-manufactured or specialty filtering material allowed.”

Old T-shirts, wood fibers and mushrooms are a few of the materials used by students in the past eight years to create filters. Students have eight to nine weeks to design, analyze and test their approach to filtration. During the final week of the project, their filter is officially tested and graded.

“This isn’t just a ‘yay, let’s play around in the lab’ type of project,” Davis said. “It has a performance requirement – the filter has to actually work."

And, thanks to ingenuity Davis continues to find remarkable, they do.

“We challenge students to filter very dirty, or ‘turbid’, water down to 0.1 Nephelometric Turbidity Units (NTU) or below, so any filter that achieves this limit is impressive to me,” he said.

NTU is a measure of how cloudy a water sample appears. Water that is safe to drink needs to be at 1 NTU or below. The project tasks students with getting a turbid water sample to below 10 NTU. That requires removing suspended solids that harbor pathogens and hinder disinfection. Once the water is cleared of sediment, a final chemical treatment step can effectively neutralize any remaining viruses and bacteria.

“But the project focuses primarily on the filtration component, and this mostly works by simply providing a material like sand or cotton that entraps those sediment particles,” Davis said. “Some of that entrapment is physical, but a lot is due to the positive-negative charge attraction of the suspended solids and the filter material.”

Davis initially keeps that bit of information to himself.

“Students aren’t given that explanation, or even told how filtration works – they have to research this on their own,” he said. “Some figure it out through trial and error, some do a lot of research first, but all of them inevitably end up relying on the Engineering Design Process to help guide their designs, which is really the point of the project – to show that engineers have to solve problems.”

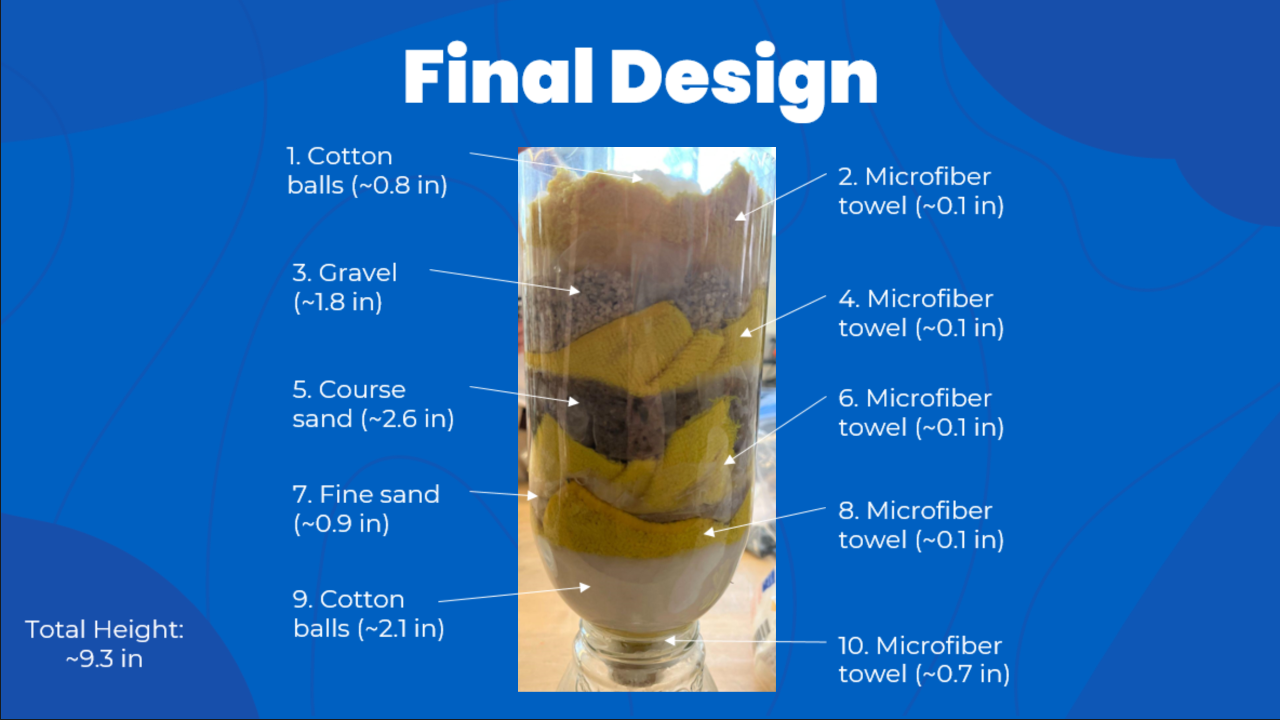

Katherine Shaw, a senior in biosystems engineering, took the course in the fall of 2023. Her team used a combination of sand, rocks, gravel and toilet paper, all layered inside a plastic water bottle.

Shaw’s team went through several tests, adjusting the size of the bottle and materials, and eventually saw results.

The team was initially given a water sample that measured at 462 NTU. Their initial design reduced the sample to about 14 NTU, and their second design brought it down to 7 NTU.

Shaw said the project gave her understanding of the engineering design process and reinforced the importance of prototyping, testing, and redesigning.

“Knowing the steps of the process and understanding the ‘why’ behind it helped my group develop an efficient and well-designed filter, as well as teaching me skills for future engineering projects and collaboration,” she said.

That’s the idea, Davis said.

“It’s a very dynamic experience for students. It’s also very hands-on, which students really enjoy.”

Media Contact: , jdh0123@auburn.edu, 3343190721

Sand, rocks, gravel and toilet paper are some of the materials students in Jonathan Davis' BSEN 2210 Engineering Methods for Biological Systems course use to create workable water filters.